Best Pvc Pipe Cutters

From leading brands and best sellers available on the web.

RIDGID

28%OFF

RIDGID 30088 RC-2375 Aluminum 2" Ratchet Action Pipe and Tubing Cutter for Plastic and Multilayer Tubing, 1/8" to 2-3/8" O.D. Capacity, Small

LIBRATON

Libraton PVC Pipe Cutter, Up to 2-1/2", Ratchet Pipe Cutter Heavy-Duty, Pex Cutting Tool for Cutting PEX, PVC, PPR Plastic Hoses and Plumbing Pipe

RIDGID

RIDGID 23498 Model RC-1625 Aluminum Ratchet Action 1/8" to 1-5/8" Plastic Pipe And Tubing Cutter, Silver, Small

RIDGID

13%OFF

Ridgid 31642 model 152 Quick-Acting Tubing Cutter, 1/4" to 2-5/8" Tube Cutter

RIDGID

21%OFF

Ridgid - CC247 RIDGID 40617 Model 101 Close Quarters Tubing Cutter, 1/4-inch to 1-1/8-inch Tube Cutter Silver

RIDGID

Ridgid 151 1/4" to 1-5/8" Quick Acting Tubing Cutter, Small

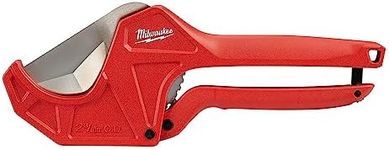

Milwaukee

Milwaukee 2-3/8 In. Ratcheting Pipe Cutt

Bates Choice

17%OFF

Bates- PVC Pipe Cutter, Cuts up to 1-1/4", Ratcheting PVC Pipe Cutter Tool, Pipe Cutters PVC, PVC Pipe Shears, PVC Cutter, Plastic Pipe Cutter, PEX Pipe Cutter, PVC Cutter Tool, PVC Ratchet Cutter

KLEIN TOOLS

Klein Tools 50063 Ratcheting PVC Pipe Cutter, Cuts 1-1/4-Inch I.D. PVC, CPVC, PEX Pipes, One-Handed Operation, Replaceable Blades

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Most Popular Categories Right Now